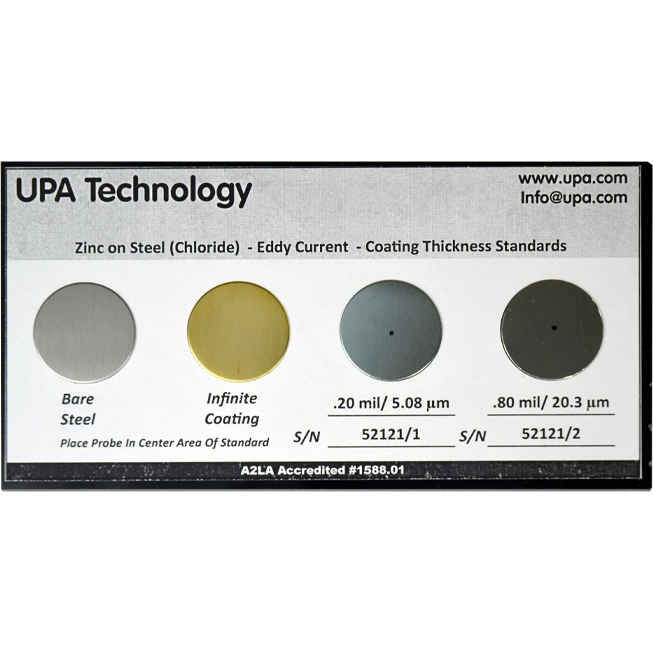

Calibration and Thickness Standards Plated Eddy Current Calibration Standards

Eddy Current instruments measure plating thickness based on the conductivity of the plated deposit. Plating baths will vary in the deposit conductivity characteristics which affect the resulting measurements. Bath chemistries and use of brighteners cause differences in the resulting plated deposits thus it is always best to use standards plated from your specific bath. This is especially true with Nickel standards since a slight nickel bath difference makes a large conductivity difference.

This is why UPA Technology offers custom plated standards made from your specific bath. Using custom eddy current standards plated using your plating bath insures that the calibration standards match the plated deposit characteristics of your parts. Using eddy current standards plated from your specific bath provides measurements that will correlate closely with X-Ray measurements. Using standards made from the same bath commonly provides accuracy within +- 0.5 microns (20u”) of the actual thickness. We are the only manufacturer to offer this service…and we offer custom standards at the same price as regular sets!

For more information or a standards quotation

Talk To An Expert

When you call UPA, you will speak with a real person who will direct you to a product or technical specialist to answer your questions, assist with your requirements or provide applications support.